Delta 18-900l Parts

Drill Delta L Instruction Manual Damaged parts can cause start-up of a machine by a child or visitor could cause further damage to the machine and/or. Delta L Inch Laser Drill Press - Power Core Drills - hatenablog.com Taladro De Soporte De PrensaMesa De TrabajoHerramientas De. Check for alignment of moving parts, binding of moving parts, breakage of parts, .. D-1 FOREWORD Delta Model L 18" ( mm) Drill Press With Lasers is a.

No se aplican tarifas de importación adicionales en la entrega. No se realizan envíos a España Ver detalles. Ubicación del artículo:.

Santee, California, Estados Unidos. Realiza envíos a:. Estados Unidos y muchos otros países Ver detalles. Para información adicional, consulta los Términos y condiciones del Programa de envíos globales - se abre en una nueva ventana o pestaña Este importe incluye los aranceles, los impuestos, la correduría y otras tarifas aplicables.

Pagos con tarjeta de crédito procesados por PayPal. Tarifas de envío internacional pagadas a Pitney Bowes Inc. Informar sobre un artículo - se abre en una nueva ventana o pestaña. Descripción Envíos y pagos. El vendedor asume toda la responsabilidad de este anuncio. Características del artículo Estado: Nuevo: Un artículo nuevo, sin usar, sin abrir, sin desperfectos y en el paquete original en caso de venir empaquetado. El empaquetado debe ser el mismo que se encontraría en una tienda, a menos que el artículo haya sido empaquetado por el fabricante con material no destinado a su venta en tienda por ejemplo una bolsa o caja sin etiquetas.

Ver todas las definiciones de estado : se abre en una nueva ventana o pestaña Envío y manipulación. El vendedor no ha especificado una forma de envío a España.

Contactar al vendedor - se abre en una nueva ventana o pestaña y solicita el envío a tu ubicación. No es posible calcular los gastos de envío. Ubicación del artículo: Santee, California, Estados Unidos. Hay 1. Este artículo no se envía a España. Tiempo de manipulación para envíos nacionales. Política de devoluciones. El comprador es responsable de delta 18-900l parts gastos de envío de la devolución. Detalles de pago. Reembolso si no recibes lo que habías pedido y pagas con PayPal.

Use the guards. Check to see that all safety devices are in place, secured, and working correctly to prevent injury. Remove adjusting keys and wrenches before starting the machine.

Tools, scrap pieces, and other debris can be thrown at high speed, causing injury. Use the right machine. Do not operate this machine until it is completely assembled and installed according to the instructions. A machine incorrectly assembled can cause serious injury. Knowledge is safety. Vibration can cause the machine to slide, walk, or tip over. Debris can be delta 18-900l parts at high speed. Loss of control of the workpiece can cause serious injury.

The chuck key can be thrown out at a high speed. Damaged items can cause malfunctions that lead to injuries. USE recommended speeds for all operations. A sudden slip could cause a hand to move into the bit. Serious injury to the hand can occur. Do not attempt to drill a workpiece that does not have a flat surface against the table, or that is not secured by a vise. Prevent the workpiece from rotating by clamping it to the table or by securing it against the drill press column.

A moving drill bit, cutting tool, or sanding drum can cause serious injury. Loss of control of the workpiece can cause severe injury. Serious injury can result. Someone else might accidentally start the machine and cause serious injury to themselves. Refer to them often and use them to instruct others. Additional safety rules for the laserS Safety Instructions for Lasers Read and understand all instructions.

For your own safety, read the tool instruction manual before using any accessory. Failure to heed these warnings may result in personal injury and serious damage to the tool and the accessory. Laser Radiation Exposure. Do not disassemble or modify the laser. There are no user serviceable parts inside. Serious eye injury could result.

Hazardous Radiation. Use or modification of the tool for anything other than its designed purpose may result in hazardous radiation exposure. Power tools create sparks which may ignite the dust or fumes. Lasers are dangerous in the hands of untrained users.

Service or maintenance performed by unqualified personnel may result in injury. Leaving the laser on increases the risk of staring into the laser beam. Modifying delta 18-900l parts tool may result in Hazardous Laser Radiation Exposure. Serious eye injury may result. Removing labels increases the risk of exposure to radiation. Laser warning nm Class IIIa Laser Also, the warning label is located on the drill press as shown: Warning Labels For your convenience and safety, the following label is on your laser: Laser Warning Label Fig.

The circuit should be protected by a circuit breaker or time delay fuse. All line connections should make good contact. Running on low voltage will damage the machine. Do not expose the machine to rain or operate the machine in damp locations. This machine must be grounded while in use to protect the operator from electric shock. All grounded, cord-connected machines: In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

This machine is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If delta 18-900l parts or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instruction are not completely understood, or if in doubt as to whether the machine is properly grounded. Repair or replace damaged or worn cord immediately. Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than volts: If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig.

B, the machine will have a grounding plug that looks like the plug illustrated in Fig. A temporary adapter, which looks like the adapter illustrated in Fig. C may be used to connect this delta 18-900l parts to a matching 2-conductor receptacle as shown in Fig.

C, if a properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the adapter is used, it must be held in place with a metal screw. In all cases, make certain that the receptacle in question is properly grounded.

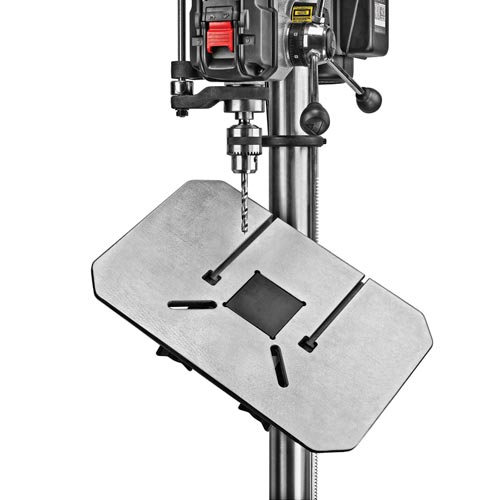

If you are not sure, have a qualified electrician check the receptacle. B Fig. When using an extension cord, be sure to use one heavy enough to carry the current of the machine. D shows the correct gauge to use depending on the cord length. The L has a tilting table for angle drilling. Side edges and parallel slots are provided for fast workpiece clamping. The laser helps users target the workpiece exactly where the drill bit will enter the material.

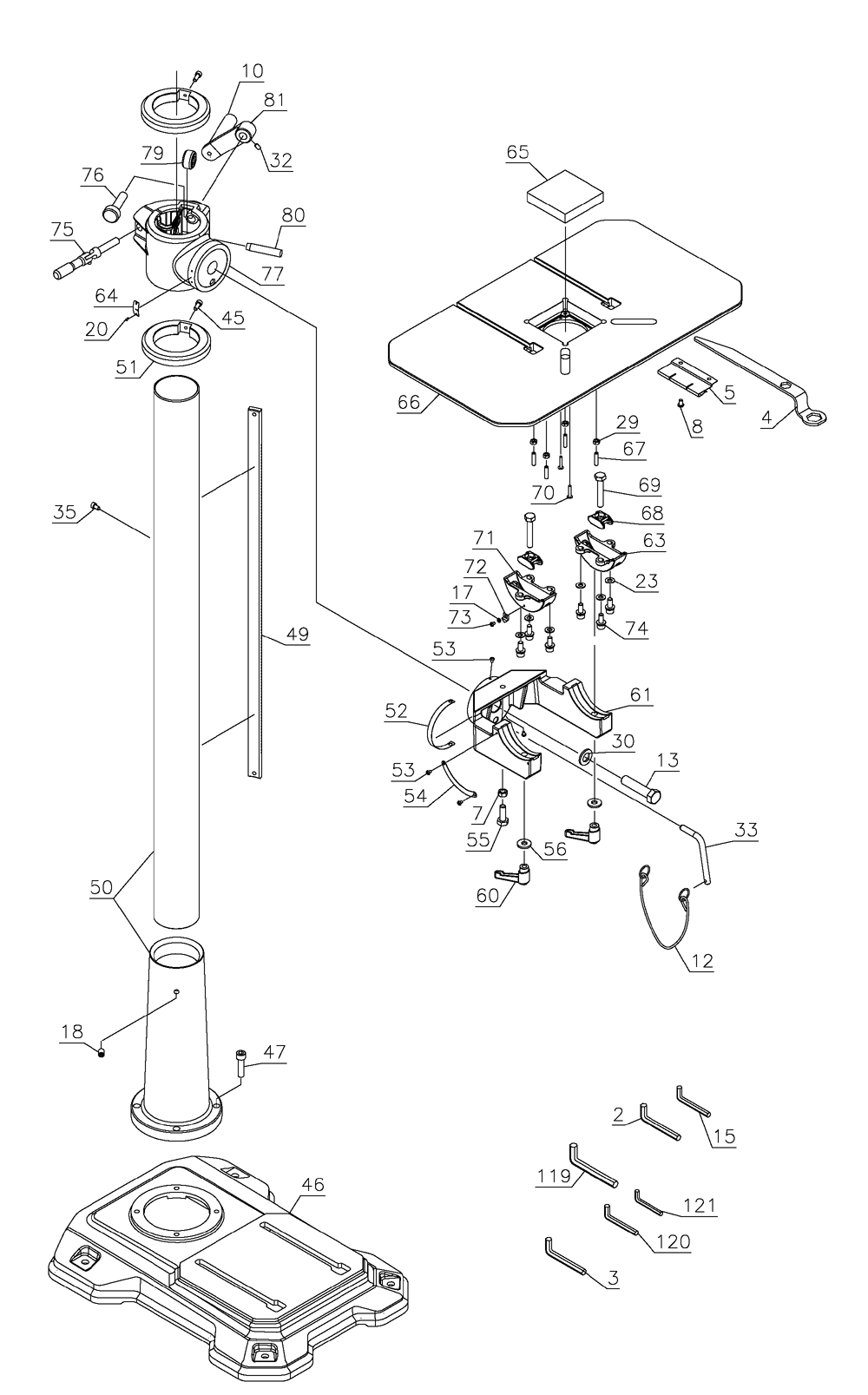

All other illustrations contained in the manual are representative only and may not depict the actual labeling or accessories included. These are intended to illustrate technique only. Base 2. Column 3. Rack 5. Table supports 6. Arbor 7. Table Clamp Handle 8. Belt tensioner handle 9. Table Raising and Lowering Handle Table LED Light Pinion shaft handles Table adjustment wrench and drift key Chuck Chuck key M6 x 1 Locknut Button head screw Lockwasher Washer Remove the rust-preventative oil from unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your machine. To reduce the risk of injury, always use at least two people when lifting. After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

If you plan to use your drill press in a permanent location, you must secure the drill press base to the supporting surface with fasteners not supplied through the four delta 18-900l parts holes A Fig. If your drill press is not permanently fastened to the floor it may be mounted to a plywood board to improve stability and prevent tipping. Do not make the mounting board from particle board since particle board breaks easily. Use a plywood board base with the minimum dimensions as shown in Fig.

Delta 18-900L Drill User Manual

Place the drill press base centered on the plywood D. Make sure that the plywood extends a minimum of 3" Mark four holes C Fig. D C 24" NOTE: Place a piece of scrap wood underneath the supporting plywood surface when drilling the through holes so that the drill bit will not damage the material beneath the plywood supporting surface.

Fasten the drill press base to the mounting plywood board using the carriage bolts, flat washers, lockwashers, and hex nuts described above not supplied. Countersink the holes for the carriage bolt heads and flat washers under the board so that the bolt heads are flush with or below the bottom surface of the board after you insert them up through the holes below the supporting surface.

Use a flat washer, lock washer and hex nut above the drill press base to fasten the screws. L Fig. A ttach the column E Fig.

Attach the table raising and lowering handle H Fig. Tighten the set screw J against the flat on the shaft with the 3 mm hex wrench supplied. Thread the table clamp handle K Fig. Align the bolts M Fig. Install the washers and forward tilt knobs as shown in Fig. Tighten securely. NOTE: The bolts in the trunnion are moveable.

To install knobs more easily, insert a flathead screwdriver O Fig. Place the drill press head P Fig. NOTE: Be sure the head-locking screws R are do not block the drill press head from fully seating on the delta 18-900l parts. P R To reduce the risk of injury, always use at least two people when lifting.

Align the head P Fig. Tighten the two head-locking screws R Fig. NOTE: Remove the rust-preventative oil from the chuck using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol. Push delta 18-900l parts spindle delta 18-900l parts V Fig.

To avoid damage to the delta 18-900l parts, prevent the cleaning solution from AVIS coming in contact with the laser pod. You can clean the laser pod with a dry cotton cloth. Hold the chuck on the taper of the spindle. Tap it with a soft-tip hammer Z Fig. EE Fig. Remove three 6 mm screws one shown at DD Fig. FF FF 3. Remove plastic cable tie. Push excess wire into the headstock.

One is shown at DD. Press chuck key into the holder as shown in Figure HH Fig. Place M6 x 1 locknut LL Fig. Over time, it will become necessary to replace this piece.

To replace the old insert : 1. Remove two screws from holes YY Fig. Remove old insert and place your new insert into the table Fig. If the insert is not level with the table, adjust the four jack screws JJ Fig. When the table insert is level, tighten the locking nut on each screw. Hold down on the insert and secure it in place with the 2 screws that were removed in Step 1.

Insert screws in holes YY Fig. Place the lockwasher under the screw head Z1 Fig. Y1 Fig. To turn drill press on, lift switch paddle KK Fig. To turn drill press off, push switch paddle KK Fig. LL KK Fig. NN Fig. Make sure that nothing is on the table and that the workpiece is clamped down.

Falling objects can cause an injury. Tilting table back to front from zero 0 to 45 degrees To adjust: 1.

Delta 18 900L 18 Inch Laser Drill Press 2019 review with Pros & Cons

Loosen the two forward tilt knobs OO Fig. Adjust the table to your desired angle. The scale PP Fig. Tighten the knobs OO Fig. A positive stop screw QQ Fig. Adjust this stop by turning the hex head of the stop screw RR Fig. Tighten the locknut SS Fig. Tilting table right to left from zero 0 to delta 18-900l parts degrees An index pin is included for the 0 degree position delta 18-900l parts the table.

To adjust: 1. Loosen the table bolt TT Fig. Pull out the index pin UU Fig. Rotate the table to your desired angle. The tilt scale VV Fig. Use this scale for accuracy. Tighten the table bolt TT Fig. When you return the table to zero, re-insert the index pin UU Fig. PP Fig. You can lock the quill at any point in its travel by positioning locking nut WW against the stop. To position nut, push the button in and slide it along the threaded rod. UU VV Fig.

However, to adjust, if necessary: To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. Loosen nuts YY but do not remove. Make sure that the delta 18-900l parts housing ZZ remains engaged with head casting S.

Loosen nut XX only enough to make spring housing YY rotatable. Loosening nut too much can be dangerous and cause personal injury. Spring inside housing is under tension and will try to unwind if not held securely.

Spring housing should still be held snugly to head casting by the nut but be loose enough to rotate the spring housing to desired spring tension. While holding the spring housing Fig. Tighten the two nuts YY Fig. YY ZZ Fig. Replace plastic cap. Be careful not to release the spring housing while adjusting the spring tension as it may rotate rapidly from the spring tension. B1 B Fig. E1 E1 Laser Light. Do not stare into the beam, aperture, or into a reflection from a mirror-like surface.

C1 D1 Laser alignment is preset at the factory. If needed, the alignment can be adjusted by following the steps below: To check if the lasers are perpendicular to the table, do this: 1. Using a carpenter's square or similar device, draw a straight line C1 Fig. Place board on its edge as shown in Fig. Make sure delta 18-900l parts board is placed over the middle of the table insert D1 Fig. Turn laser on so the red lines are shining on board as shown. Check to see if both red lines E1 Fig.

If they are not: 1. Using an included hex key, turn the front screw F1 Fig. Repeat this step for the left laser pod and its line using its front screw F1 Fig. To check to see if the lasers intersect at the drill point: 1. Lay board flat on table Fig. Using a small drill bit with the machine off, lower the drill bit and make an impression in the board.

For both lasers, use the same hex key in the the back screw G1 Fig. Recommended operating speeds are in RPMs. A belt-positioning speed chart is located on the inside top cover of the drill press. Lift cover H1 Fig. Move belt tension lever handle I1 Fig. Choose the appropriate speed for the tool you are using and position the belts on the pulleys accordingly.

See chart Fig.

parts can cause further damage to the machine and/ .. Delta Model L 18" ( mm) Drill Press With Lasers is a heavy-duty machine with a 3/4 HP, V. DE SERVICIO Y PÓLIZA DE GARANTÍA. LÉASE ESTE INSTRUCTIVO. ANTES DE USAR EL PRODUCTO. hatenablog.com 18" ( mm).

NOTE: The belts are ribbed with grooves, so make sure the belt grooves match up with the pulley grooves. Lift handle and move to left as shown in Fig. It is set with the proper tension for the belts. NOTE: Fig. Drilling holes to depth To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. Place bit L1 in chuck Fig.

Lower the bit until it touches workpiece M1 Fig. Raise the quill locking nut N1 by pressing button and raising it up against the depth stop bracket O1. Turn scale on the pinion P1 Fig. Set depth 1. Remove the workpiece and rotate pinion handles to lower quill to desired drilling depth as registered on the scale. Holding the quill at this depth, raise the quill locking nut N1 Fig. Still holding the spindle, lower the depth stop nut Q1 Fig.

Lower the quill locking nut N1 Fig. To reduce the risk of injury, tighten all lock handles before starting the machine. Connect the machine to the power source and drill a test hole to check the adjustment.

Readjust, if necessary, by rotating the stop nut Q1 Fig. You do not have to depress the button to rotate the stop nut Q1. NOTE: After installing a drill bit, use the supplied key to tighten all three locations on the chuck. To reduce the risk of injury, properly support long or wide work-pieces. To reduce the risk of injury, do not place more than pounds kg of weight on the table. If it is not possible to support the workpiece against the column, clamp the workpiece to the table.

L1 M1 Fig. To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs.

Insert the smooth end of drill bit L1 Fig. Center the drill bit L1 Fig. Turn the chuck key T1 Fig. Tighten all three chuck jaws to secure the drill bit sufficiently to prevent slipping. Remove the chuck key T1 Fig. The chuck key is equipped with a self-ejecting pin U1 which helps minimize the potential for the key to be left in the chuck. The spindle adapter and chuck can be delta 18-900l parts for the purpose of using shanks with a 2 morse taper.

Align the slot in the quill V1 Fig. Insert the drift key X1 Fig. Tap the drift key X1 Fig. S1 Use the recommended speed for the the drill press bit and workpiece. Twist drills, usually intended for metal drilling, can also be used for boring holes in wood. However, machine spur bits are generally preferred for working in wood. These bits cut a flat-bottom hole and are designed for removal of wood chips.

Do not use hand bits screw tip. At drill press speeds, they lift and rotate the workpiece. W1 V1 For through boring, align the workpiece so that the bit will go through the center hole in the table. Scribe a vertical line on the front of the column and a matching mark on the table bracket and the drill press head, so that the table and drill press head can be clamped in the center position at any height.

Use a scrap piece of wood as a base block under the work to reduce splintering and protect the point of the bit. Use clamps to hold metal workpieces. Never hold the workpiece in your bare hand. The drill bit can seize the work at any time, especially when breaking through the workpiece and delta 18-900l parts damage to the machine or injury to you. The drill bit will break if delta 18-900l parts workpiece strikes the column.

Any tilting, twisting, or shifting results not only in a rough hole, but also in bit breakage. For flat work, lay the workpiece on a wooden base and clamp it firmly against the table to prevent it from turning. If the workpiece is of irregular shape and cannot lay flat on the table, securely block or clamp it. All plastic parts should be cleaned with a soft damp cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Also, check for blown fuses or open circuit breakers in the line. Or use a commercially available protective delta 18-900l parts designed for this purpose. To clean cast iron tables of rust, you will need the following materials: a medium sized scouring pad, a can of spray lubricant and a can of degreaser. Apply the spray lubricant and polish the table surface with the scouring pad.

Degrease the table, then apply the protective product as described above. Also, be sure to clean any dust or contamination from the hole using a small brush like an old toothbrush. K Fig. For a parts list or to order parts, visit our website at www. You can also order parts from your nearest factory-owned branch, Authorized Warranty Service Center or by calling Technical Service Manager at to receive personalized support from one of our highly-trained representatives.

All repairs made by our delta 18-900l parts centers are fully guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by others. Be sure to include all of the information shown on the nameplate of your tool model number, type, serial number, date code, etc. For further detail of warranty coverage and warranty repair information, visit www.

This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces. For products sold in Latin America, see country specific warranty information contained in the packaging, call the local company or see website for warranty information. Please visit delta 18-900l parts Web Site www.

Afin de vous aider à identifier cette information, nous avons utilisé les symboles ci-dessous. Le risque associé à de telles expositions varie selon la fréquence à laquelle on effectue ces travaux.

Pour réduire toute exposition à ces produits : travailler dans un endroit bien aéré, en utilisant du matériel de sécurité homologué tel un masque antipoussières spécialement conçu pour filtrer les particules microscopiques. Portez des dispositifs de protection des yeux et de l'ouïe. Utilisez toujours des lunettes de sécurité. Des lunettes ordinaires ne constituent pas des lunettes de sécurité.

Utilisez des équipements de sûreté homologués. Les dispositifs de protection des yeux doivent être conformes aux normes ansi z Les dispositifs de protection de l'ouïe doivent être conformes aux normes ansi S3.

Porter une tenue appropriée. Pas de cravates, de gants, ni de vêtements amples. Enlever montre, bagues et autres bijoux. Rouler les manches. Les vêtements ou les bijoux qui se trouvent pris dans les pièces mobiles peuvent entraîner des blessures. Ne pas utiliser la machine dans un environnement dangereux.

Les moteurs et interrupteurs des outils pourraient provoquer des étincelles et enflammer des vapeurs. Garder les outils et les machines en parfait état. Suivre les instructions pour lubrifier et changer les accessoires. Inspecter les pièces pour déceler tout dommage. Les zones et établis encombrés favorisent les accidents. Garder les enfants et les visiteurs à distance.

Les enfants et les visiteurs peuvent se blesser. Éviter le démarrage accidentel. Un démarrage accidentel peut entraîner des blessures. Utiliser les dispositifs protecteurs. Vérifier que tous les dispositifs protecteurs sont bien en place, bien fixés et en bon état de marche pour éviter les blessures.

Enlever les clés de réglage et celles de serrage avant de mettre la machine en marche. Les outils, les chutes et les autres débris peuvent être projetés violemment et blesser. Utiliser la bonne machine. Utiliser les accessoires recommandés.

Utiliser le cordon prolongateur approprié. Plus le chiffre est petit, plus le fil est gros. Fixer la pièce. Utilisez les brides ou un étau pour tenir l'objet si pratique. La perte de commande delta 18-900l parts objet peut causer des dommages. Avancer la pièce dans le sens contraire à la rotation de la lame, de la fraise ou de la surface abrasive.

Ne pas forcer la machine en avançant la pièce trop vite. Ne pas se pencher au-dessus de la machine. Ne jamais monter sur la delta 18-900l parts. Ne jamais laisser la machine en marche sans surveillance. Couper le courant. Un enfant ou un visiteur pourrait se blesser. Le démarrage accidentel de la machine par un enfant ou un delta 18-900l parts peut entraîner des blessures. Rester vigilant, attentif, et faire preuve de bon sens.

L'utilisation de cet outil peut produire et disperser de la poussière ou d'autres particules en suspension dans l'air, telles que la sciure de bois, la poussière de silicium cristallin et la poussière d'amiante. Dirigez les particules loin du visage et du corps. Faites toujours fonctionner l'outil dans un espace bien ventilé et prévoyez l'évacuation de la poussière. Utilisez un système de dépoussiérage chaque delta 18-900l parts que possible. L'exposition à la poussière peut causer des problèmes de santé graves et permanents, respiratoires ou autres, tels que la silicose une maladie pulmonaire grave et le cancer, et même le décès de la personne affectée.

Évitez de respirer de la poussière et de rester en contact prolongé avec celle-ci. En laissant la poussière pénétrer dans vos yeux ou votre bouche, ou en la laissant reposer sur votre peau, vous risquez de promouvoir l'absorption de substances toxiques. Une machine mal assemblée peut provoquer des blessures graves. La connaissance est synonyme de sécurité. Delta 18-900l parts débris peuvent être projetés à grande vitesse.

Des articles endommagés peuvent provoquer des défaillances qui mèneraient à des blessures. En glissant inopinément, votre main pourrait percuter la mèche. De graves blessures à la main peuvent survenir. Une mèche, un outil de coupe ou un cylindre de contact en mouvement peut provoquer de graves blessures.

De graves blessures pourraient survenir. Veuillez vous reporter à la norme ANSI Les consulter souvent et les utiliser pour donner des directives aux autres.

4,369 results

Ne pas démonter ou modifier le laser. Des lésions oculaires graves pourraient en résulter. Les outils électriques peuvent produire des étincelles qui pourraient enflammer toute émanation ou poussière ambiante.

Tout entretien ou maintenance effectué delta 18-900l parts une personne non qualifiée comporte des risques de dommages corporels. Laser de classe Ce circuit doit être protégé par un disjoncteur homologué ou un fusible à retardement. Si on utilise un cordon prolongateur, ce cordon doit être à trois fils, avoir unefiche à trois broches et une prise de courant à trois cavités, mise à la terre qui correspond à la fiche de la machine.

Toutes les connexions électriquesdoivent établir un bon contact. Le fonctionnement sur une basse tension endommagera la machine. La fiche doit être branchée dans une prisede courant correspondante, installée de façon adéquate etmise à la terre conformément à tous les codes et règlements locaux. Réparer ou remplacer sans délai tout cordon endommagé ouusé.

Machines avec cordon mis à la delta 18-900l parts prévues pour uneutilisation sur une alimentation nominale inférieure à volts: Si cette machine est prévue pour être utilisée sur un circuit quicomporte une delta 18-900l parts semblable à celle illustrée à la figure B, la machine devra comporter une fiche mise à la terre semblableà celle illustrée à la figure B. Quand un adaptateur est utilisé,celui-ci doit être retenu en place par une vis en métal. Dans tous les cas, s'assurer quela prise en question est bien mise à la terre.

Dans le doute, demander à un électricien compétentde vérifier la prise. C Fig. S'assurent votre corde de prolongation est en bon état. En utilisant une corde de prolongation, soyez sûr d'employer un assez lourd pour porter le courant de la machine.

Une corde trop petite causera une baisse dans la tension secteur, ayant pour résultat la perte de puissance et de surchauffe. D, expositions la mesure correcte à employer selon la longueur de corde. En cas de doute, utilisez la prochaine mesure plus lourde. Plus le nombre de mesure est petit, plus la corde est lourde. Il comprend également des bords latéraux et des fentes parallèles permettant le blocage rapide de la pièce à travailler. Colonne 3. Delta 18-900l parts de crémaillère 2 4. Crémaillère 5.

Support de table 6. Arbre 7. Poignée de blocage de la table 8. Manette de tension de courroie 9. Goupille de 0 degré Tableau Vis à tête cylindrique à six pans creux M10 x 40 mm 4 Voyant DEL 20 Manettes de fourreau Clé de réglage de table et chasse-clé Mandrin Clé de mandrin M6 x 1 contre-écrou Vis à tête ronde Rondelle de blocage Rondelle Un démarrage accidentel peut provoquer des blessures.

Clés hexagonales fournies Maillet en caoutchouc non fourni Clés 10 mm B Fig. REMARQUE : pour fixer la base sur un panneau de contreplaqué, utiliser la quincaillerie suivante : 4 vis à tête bombée M8 x 1,25 x mm, 8 rondelles plates M8, 4 rondelles de blocage M8 et 4 écrous hexagonaux M8 x 1, Utilisez un panneau de contreplaqué aux dimensions minimales illustrées en fig.

Centrez la base de la perceuse à colonne sur le contreplaqué D. Tracez quatre repères C Fig.

Puis percez des trous de 9. Utilisez une rondelle plate, une rondelle de blocage et un écrou hexagonal sur le dessus de la base pour arrimer les vis.

Tout démarrage accidentel comporte des risques de dommages corporels. Fixez la perceuse à colonne Efig. Rattachez la poignée H pour élever ou abaisser le plateau, fig. Vissez le levier de verrouillage de plateau Kfig.

Alignez les boulons Mfig. Resserrez fermement. Pour installer les manettes plus facilement, insérez un tournevis à tête plate Ofig.

Servicios De Mensajeria S.aDescarado O Dulce Sitio De CitasSitios De Citas Italianos ItalianoSingles De Boa Vista Roraima Fotos Do CentroChicas En North Fort Myers Fl MapReunion En Blanco Y Negro Barricada DiscotecasProfessor Layton Android Gratuit